Sheet Metal Straightener Feeder

Basic Info

Model No.: MFL3

Product Description

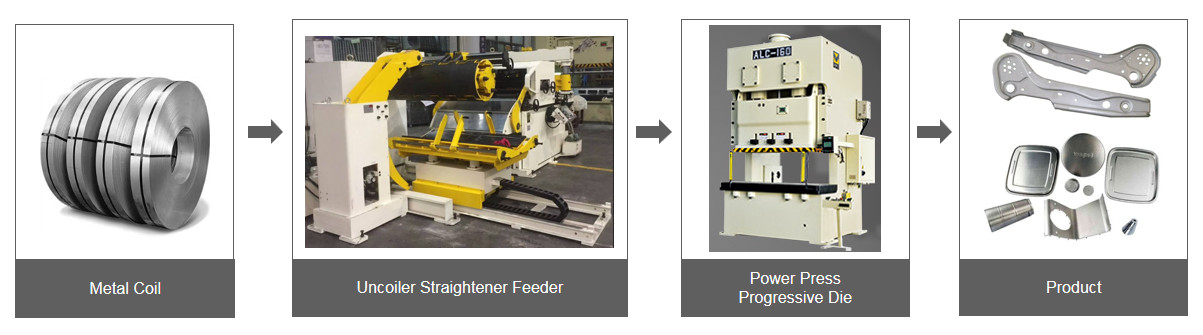

SHEET METAL STRAIGHTENER FEEDER

This is a compact feeding line, with decoiler, straightener and feeder machine in one combination unit. so called feeder-straightener, which is positioned directly at the press, the needed space for material loop of straightened material can be saved. the whole compact feeding system is only 4.5m length, which will save a lot of workspace for your press workshop.

Sheet Metal Straightener Feeder is used to uncoiling metal strip from coil stock, straightening it to required flatness and feed it to press machine for stamping process.

Thanks to a well-knit body and advanced mechanical structure, it can easily handle coil stock up to 10tons.

With the Yaskawa Servo Systems and Mitsubishi PLC control, the metal coil straightener feeder can reach ±0.15mm feeding precision.

- Decoiler---The decoiler is designed for coils with outer diameter of up to 1200mm. The coil is drawn off from above across the hinged feed table. Loading is handled by a crane or stacker. The decoiler is expanded manually or Hydraulic. The coil is restrained by a pneumatic pressure roller.

- The feeder-straightener is supplied with material out of a (in comparison) very small loop of not straightened material below the decoiler.

- The decoiler is equipped with a variable speed drive as well as with a very sensitive loop control. By this way it is assured that there always will be enough material available for supply of the feeder-straightener.

- In case that feeding lengths and stroke rates do require a bigger material stock within the material loop, the Coil Feeding Line will be completed with a loop pit.

Suitable Material: CR Steel, HR Steel, Stainless, Aluminum, Copper etc.

Coil width: 50mm-1300mm

Material thickness: 0.4mm-4.5mm

Coil weight: Max.10Tons

Line speed: 20m/min

Feeding length: Max.9999.99mm

With the Yaskawa Servo Systems and Mitsubishi PLC control, the metal coil straightener feeder can reach ±0.15mm feeding precision.

SPECIFICATION

| Sheet Metal Straightener Feeder | |||||

| Specification | |||||

| Model | MFL3-300 | MFL3-400 | MFL3-600 | MFL3-800 | MFL3-1000 |

| Stock Width(mm) | 50-300 | 50-400 | 50-600 | 70-800 | 70-1000 |

| Stock Thickness(mm) | 0.4-4.5 | ||||

| Max.Coil Weight(kg) | 5000 | 5000 | 5000 | 5000/7000 | 7000 |

| Max.Coil O.D.(mm) | Φ1400 | ||||

| Coil I.D.(mm) | Φ508 | ||||

| Feed Length(mm) | ~500* | ||||

| Max.Line Speed(m/min) | 16-24 | ||||

| Straightener Rolls(piece) | up 4 / down 3 | ||||

| Feed Rolls(set) | 1 | ||||

| Main Motor | AC4.4 | AC4.4 | AC4.4 | AC5.5 | AC7.5 |

| Mandrel Expansion | hydraulic | hydraulic | hydraulic | ||

| Reel Motor(kw) | 2.2 | 2.2 | 2.2 | 2.2 / 3.7 | 3.7 |

| Power(v) | 3 Phase 220V/380V/50HZ | ||||

| Operating Air(Mpa) | 0.49 | ||||

| Straightening Performance | |||||

| Material Tech-info of thickness & Width | MFL3-300 | MFL3-400 | MFL3-600 | MFL3-800 | MFL3-1000 |

| 0.3~0.8 | 400 | 400 | 600 | 800 | 1000 |

| 1 | 750 | ||||

| 1.2 | 700 | 600 | |||

| 1.6 | 590 | 480 | 430 | ||

| 1.8 | 500 | 420 | 380 | ||

| 2 | 430 | 370 | 330 | ||

| 2.3 | 360 | 320 | 290 | ||

| 2.8 | 370 | 370 | 290 | 250 | 230 |

| 3.2 | 300 | 300 | 250 | 220 | 200 |

| 4.5 | 160 | 160 | 160 | 150 | 110 |

Remark:1)The above figures are the material having yield strength σs=245N/mm² ,Max. tensile strength σb=392 N/mm²)

2)Specifications are subject to change for improvement without notice.

PICTURES

PRODUCT APPLICATION

Sheet Metal Straightener Feeder is suitable for automobile stamping, appliances manufacturing, computer and electronic componets, hardware and metal parts etc industry.Automotive Parts: Bracket, Damper, Barke Pad, Tie Bar, Electric Accessory, Shell Parts Of Printers, Computer Frame,Slide Rail of Car Seat, Splash Shield of car body and etc.

METAL SHEETS STAMPING LINE CONFIGURATION

CUSTOMER APPLICATION

Sheet Metal Straightener Feeder is working in customer's factory.

Product Categories : Coil Straightener Feeder > Uncoiler Straightener Feeder